EVs are a lot more efficient than gasoline cars; more and more people adapting to electric transportation will result in reduced transportation emissions worldwide.

Nonetheless, being a far more eco-friendly alternative to the internal combustion engine doesn't mean there isn't still room for improvement for EVs. One of the areas with room for improvement is battery recycling.

A Research team at the Swedish KTH Royal Institute of Technology developed an extremely efficient method for recycling batteries with the clever use of ultrasound.

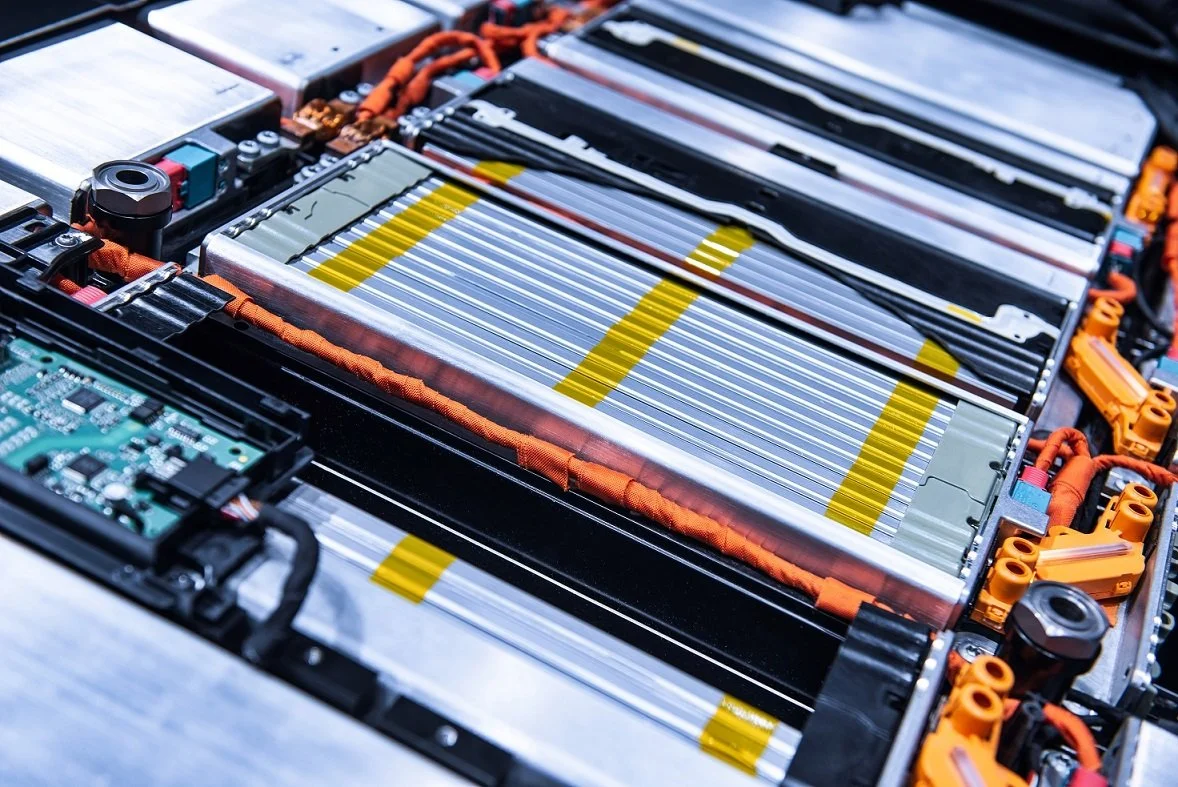

Image Credit: Gorodenkoff via Shutterstock / HDR tune by Universal-Sci

SUSTAINABLE EV BATTERY MARKET

If we are going towards a more 'EV-centric' future it is essential to have a viable and sustainable battery market. Efficient battery recycling is the backbone of such a market, providing an uninterrupted flow of reusable rare metals and other raw materials.

The researchers discovered that ultrasound can be utilized at very low frequencies to extract metal from NMC EV batteries (NMC stands for Nickel, Manganese, and Cobalt, it is the dominant battery type used in EVs).

Not only has this method proven to be more effective and almost twice as fast compared to conventional methods, it also allows for the use of mild organic citric acids as a leaching agent instead of harmful chemicals like sulfuric acid.

The ultrasound method is more efficient in recovering metal ions like nickel, lithium, and cobalt. Although excellent for EV batteries, the researchers remarked that the benefits of this method could reach beyond EVs. (Think of other products that require sustained energy storage, such as laptops and mobile phones).

An EV lithium battery pack - Image Credit: Sergii Chernov via Shutterstock / HDR tune by Universal-Sci

HOW DOES ULTRASOUND BATTERY RECYCLING WORK?

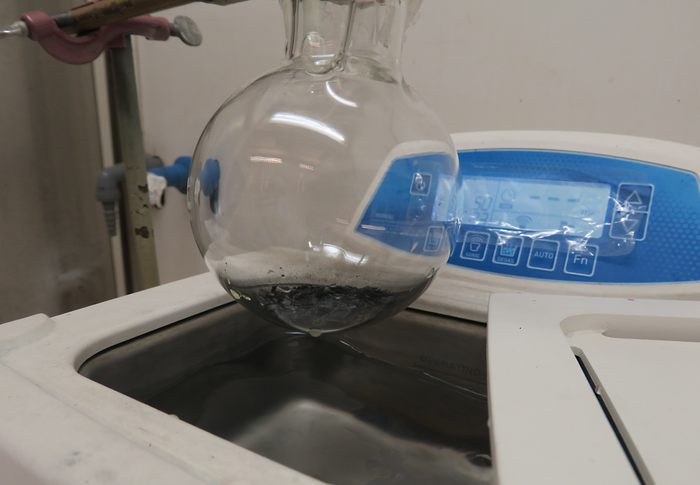

In short, ultrasonic-assisted leaching (extraction) of valuable metals from discarded batteries works with the use of baths that send high-frequency mechanical pressure waves.

The team used a frequency of 40 kHz (a tone undetectable to the human ear). These waves produce micro-bubbles that generate local temperatures of almost 5,000C when they collapse, creating highly reactive free radicals.

The resulting agitation enhances the transfer of mass in battery metals to the extent that the aforementioned harmful chemicals are no longer required to extract metals.

ULTRASOUND BATTERY RECYCLING VERSUS CONVENTIONAL RECYCLING

The research team published their findings in the scientific journal Green Chemistry. They reported impressive results.

An impression of the metal ion recovery system - Image Credit: David Callahan/KTH Royal Institute of Technology

The recovered percentage of aluminum with the use of ultrasound significantly increased (60%) versus conventional methods at the same conditions (48%).

The new method yields even more impressive recovery percentages with other metals. Maganese and lithium, for example, were recovered with reported effectiveness of 96% and 94%, respectively. Conventional methods only reach 89% for both these metals at the same conditions.

The best results were registered with nickel and cobalt. Where nickel was recovered with effectiveness of approximately 99% and cobalt recovery was practically 100%, where conventional methods only reach 91% and 87% at the same conditions.

Overall, the study had shown very impressive results on top of eliminating the need for harsh chemicals traditionally used in battery recycling. The team has now set its sights on improving the ultrasound method even further by experimenting with different frequencies and levels of intensity.

No comments:

Post a Comment